I deal for removing damaged screws.

Specifications

| Usage | Non-Hardened screws Stainless Steel screws |

|---|---|

| Material(s) | Tapered Bit:(Countersink Bit)Range of SKH Series ・(Hexshank)Alloy Tool Steel Double-ended Bit:Alloy Tool Steel Spare Bit:Range of SKH Series |

| Recommended tool(s) |

Quick Change Impact Driver (over 14.4v) Cordless Drill (over 14.4v) |

| RPm Range | Less than 3,000 rpm |

| Shank Shape |  :Hexagon :Hexagon  :Round :Round |

Caution Caution |

|

Sizes

Size:D Shank Shape:d Unit:mm

| Product No. | Name | Size | Shank Shape | Recommended screw sizes |

|---|---|---|---|---|

| 5050-S015 | 1.5mm Set | 1.5 | 6.35  |

M2.5~3 |

| 5050-S020 | 2.0mm Set | 2.0 | 6.35  |

M4~5 |

QTY(Inner Box):6pcs

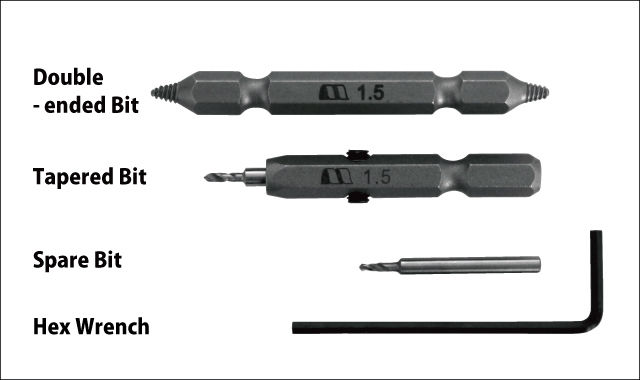

※Set contents:Double-ended Bit・Tapered Bit・Spare Bit・Hex Wrench

Assembly

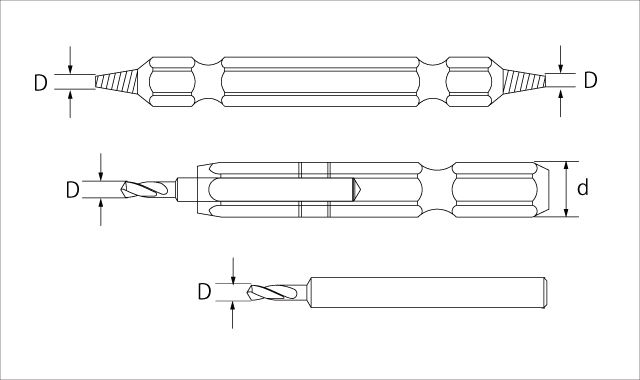

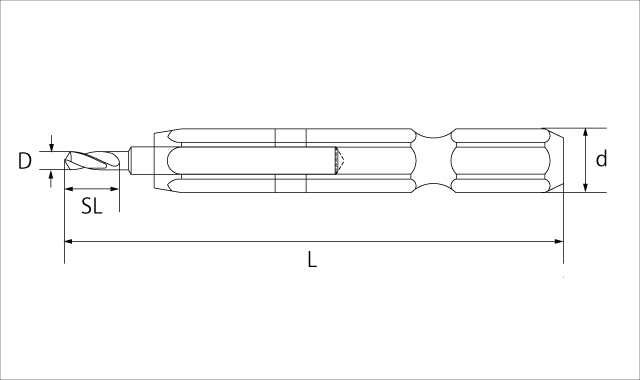

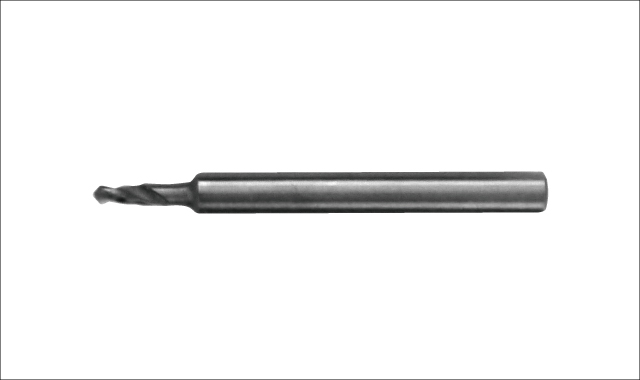

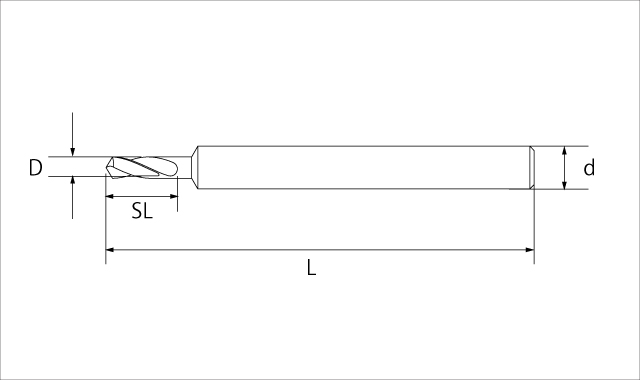

Size:D Overall Length:L Spiral Length:SL Shank Shape:d Unit:mm

| Product No. | Size | Overall Length | Spiral Length | Shank Shape |

|---|---|---|---|---|

| 5050-A015 | 1.5 | 55 | 5 | 6.35  |

| 5050-A020 | 2.0 | 55 | 5 | 6.35  |

QTY(Inner Box):6pcs

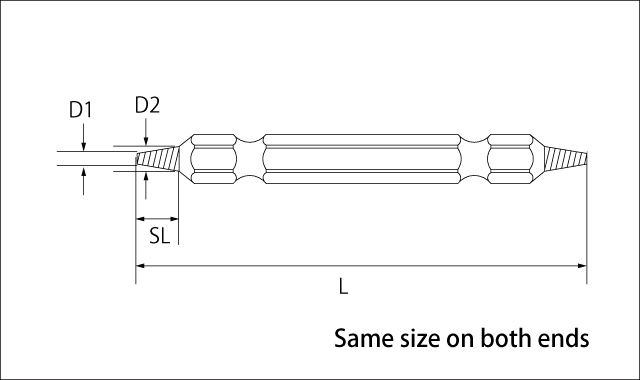

Size1:D1 Size2:D2 Overall Length:L Spiral Length:SL Unit:mm

| Product No. | Size1 | Size2 | Overall Length | Spiral Length |

|---|---|---|---|---|

| 5050-B015 | 1.5 | 3.5 | 65 | 5 |

| 5050-B020 | 2.0 | 3.5 | 65 | 5 |

QTY(Inner Box):6pcs

Size:D Overall Length:L Spiral Length:SL Shank Shape:d Unit:mm

| Product No. | Size | Overall Length | Spiral Length | Shank Shape |

|---|---|---|---|---|

| 5050-CD015 | 1.5 | 30 | 5 | 3  |

| 5050-CD020 | 2.0 | 30 | 5 | 3  |

QTY(Inner Box):6pcs

Bits of knowledge

Help

①Damaged a screw head.

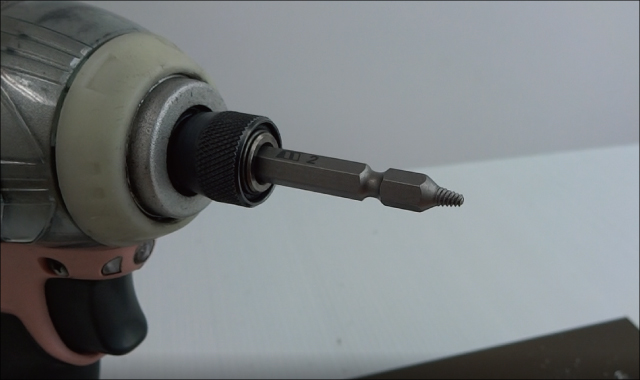

②Secure a Tapered Bit with a Quick Change Impact Driver. Be carefully to use a proper size of screw head.

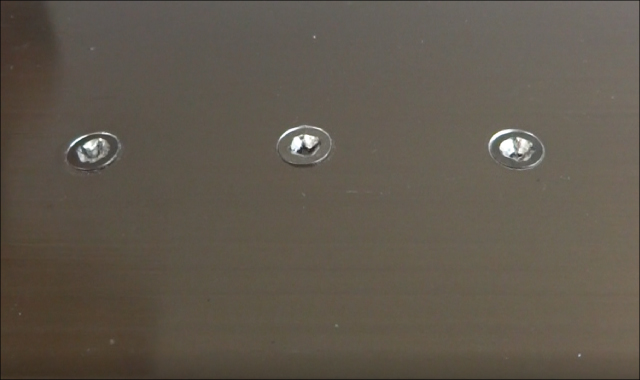

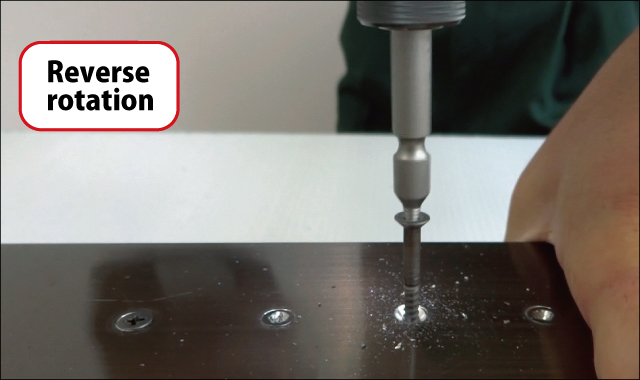

③Drill a deep hole in the center of the damaged screw.

※Do not drill unnecessary as it may break or snap.

④Drilled a hole.

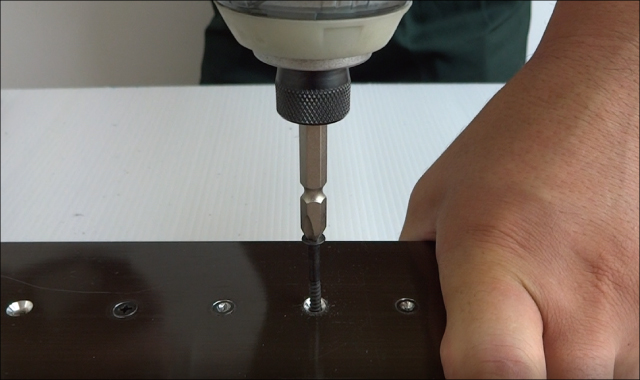

⑤Secure a Double-ended Bit with a Quick Change Impact Driver.

⑥Remove the screw with the Double-ended Bit and rotate it in reverse.

⑦Removed the damaged screw.

⑧Remove the screw out from the Double-ended Bit. Grip the screw securely with a pliers and rotate it in regular with a Quick change impact driver.

⑨Re-screw at the same place.

⑩Completed

Catalog

Movie

Associated Product